- Mobility Rising

- Posts

- Opinion: Localisation is key to building an EV industry

Opinion: Localisation is key to building an EV industry

From the newsletter

Kenya’s EV sector must embrace localisation to scale, says Tobias Alando, CEO of the Kenya Association of Manufacturers (KAM). Already, 30% of new two-wheeler registrations in Nairobi are electric, showing strong demand. Companies can still be competitive even if they source 40–50% of their materials locally, but policies need to lead to unlock local value addition.

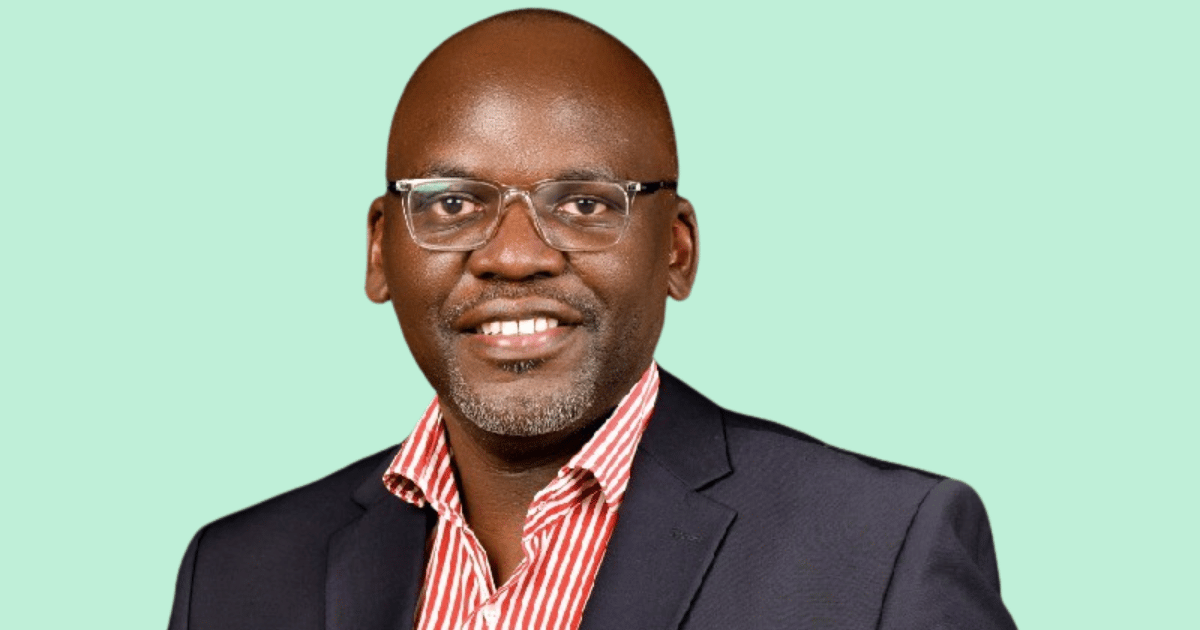

Mr Alando, CEO since January, has been with KAM for over two decades. He was previously Chief Operating Officer and Head of Membership and Governance.

“As a continent, it is paramount for us to enhance value addition for our raw materials and intermediate products and derive value from our natural resources. This will enable us to unlock significant economic benefits, create jobs, and foster sustainable development,” says Mr Alando

More details

By Tobias Alando

As Kenya embarks on its journey toward green industrialisation, the electric vehicle (EV) sector presents a generational opportunity to achieve three national priorities simultaneously: creating good jobs, improving public health, and strengthening our fiscal base.

Building Kenya’s electric vehicle industry necessitates a comprehensive policy and fiscal roadmap to accelerate the sector and position the country as a regional leader in clean and sustainable transportation. The promise of future local value addition will only materialise through strong, manufacturing-centric, and forward-looking policy and regulatory support.

However, the sector continues to contend with hindrances such as a lack of economies of scale, high cost of raw materials and tooling, high labour and energy costs, heavy tax and regulatory burden, limited access to finance and technical support, as well as customs delays and logistics challenges.

The electric value chain in Kenya is no longer theoretical. We have a diverse ecosystem of players: contract assemblers, battery assemblers, local original equipment manufacturers, frame manufacturers, software developers, and charging infrastructure companies.

Data from the Kenya Association of Manufacturers and independent analysis conducted in collaboration with Manufacturing Africa indicate that achieving 40–50% local content in electric motorcycle manufacturing is already cost-competitive, particularly when considering shipping costs, long lead times, and working capital tied up in imports.

Studies by organisations such as UNIDO and the African Development Bank highlight the opportunity for African countries to leapfrog into green industrial value chains—including electric mobility—through strategic industrial policy. This success story can be replicated in other segments of the electric vehicle industry.

The economic returns are substantial. For every direct manufacturing job created by a vertically integrated electric vehicle assembler, up to 22 additional jobs are created across the broader value chain, encompassing steelwork, plastics, maintenance, logistics, digital platforms, and after-sales services. These are not just numbers; these are livelihoods.

Kenya is currently grappling with unemployment, particularly among the youth. At the same time, our import bill for vehicles and vehicle parts exceeded Ksh150 billion ($1.2 billion) in 2023. By growing domestic production, we shall be better positioned to directly reduce our reliance on imports, enhance economic resilience and create much-needed jobs.

Localisation is a pathway to scale. In Kenya, the electric two-wheeler market is already at a considerable scale, with 30% of new registrations in Nairobi of all two-wheelers being electric. Countries such as India have shown that tying incentives to domestic value addition works.

India has put in place an initiative—Faster Adoption and Manufacturing of Electric Vehicles (FAME II)—which aims to support the electrification of public and shared transportation. The programme is implemented through subsidies provided directly by the government of India.

Under the FAME II scheme, electric two and three-wheelers only qualify for subsidies if they meet the localisation requirements of 50% or higher. The result: India’s EV manufacturing ecosystem is growing, jobs are being created, and domestic capacity is expanding.

Kenya and Africa must also be alert to global dynamics. As a continent, it is paramount for us to enhance value addition for our raw materials and intermediate products and derive value from our natural resources. This will enable us to unlock significant economic benefits, create jobs, and foster sustainable development.

By processing raw materials into finished goods for export, African nations can increase export earnings, reduce reliance on imported goods and build more resilient economies.

In response to evolving dynamics in the Kenyan automotive industry, including the emergence of electric vehicles, the push for increased local content, and a desire to strengthen local manufacturing, the Government of Kenya sought to review the existing two key legal instruments related to the electric vehicle industry.

First, is Legal Notice No. 84 of 2019 under the Tax Procedures (Unassembled Motor Vehicles and Trailers) Regulations, 2019, which seeks to regulate the importation and assembly of unassembled motor vehicles and trailers; provide tax and warehousing procedures for importers of Completely Knocked Down kits and promote local content and component manufacturing.

Second is Legal Notice No. 112 of 2020: The Tax Procedures (Unassembled Motorcycles) Regulations, 2020. The main review objective was to provide for e-mobility, whose purpose is to provide and differentiate between manufacturing and assembly; promote local content and component manufacturing; and align the sector with the evolving industrial and environmental policies.

The time to build Kenya’s electric vehicle industry is now. Given its importance to industrialisation, job creation, and the clean mobility agenda, localisation and scaling capacity will spur the industry’s growth.

This opinion piece was first published by the Business Daily.